Photo taken of HyTech Racing's competition team at Formula SAE Electric Michigan 2022.

Photo taken of HyTech Racing's competition team at Formula SAE Electric Michigan 2022.

HyTech Racing is Georgia Tech’s student-run electric race car team.

We compete in the most popular collegiate engineering competition in North America, Formula SAE.

As the president from 2021- 2022, I oversaw overall vehicle design, managed the race car's developmental timeline, organised financial outlook, and directed the operations of the team.

I was also extremely involved personally in the development of the electric drives systems on the vehicle, which includes the battery pack and the powertrain.

Furthermore, I spearheaded the development of vehicle performance modeling, which were used to guide architectural decisions.

Developing HT06, Our 2021-2022 Competition Vehicle

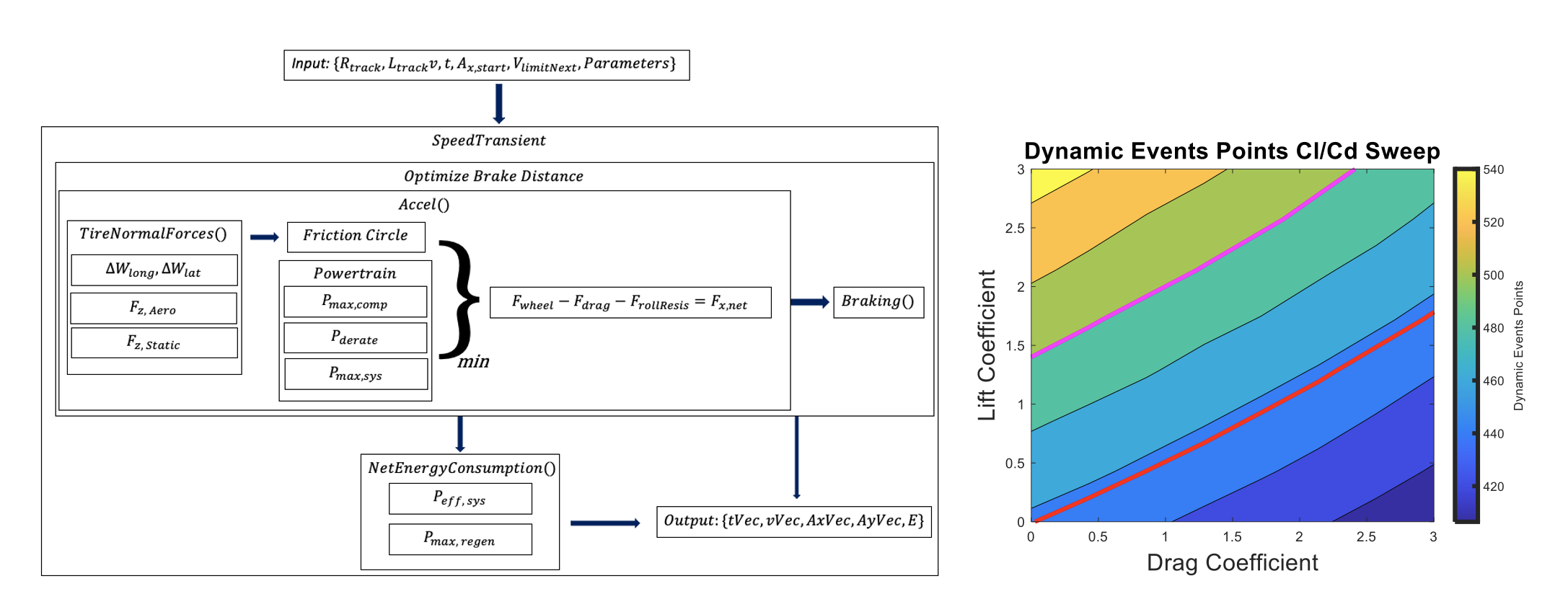

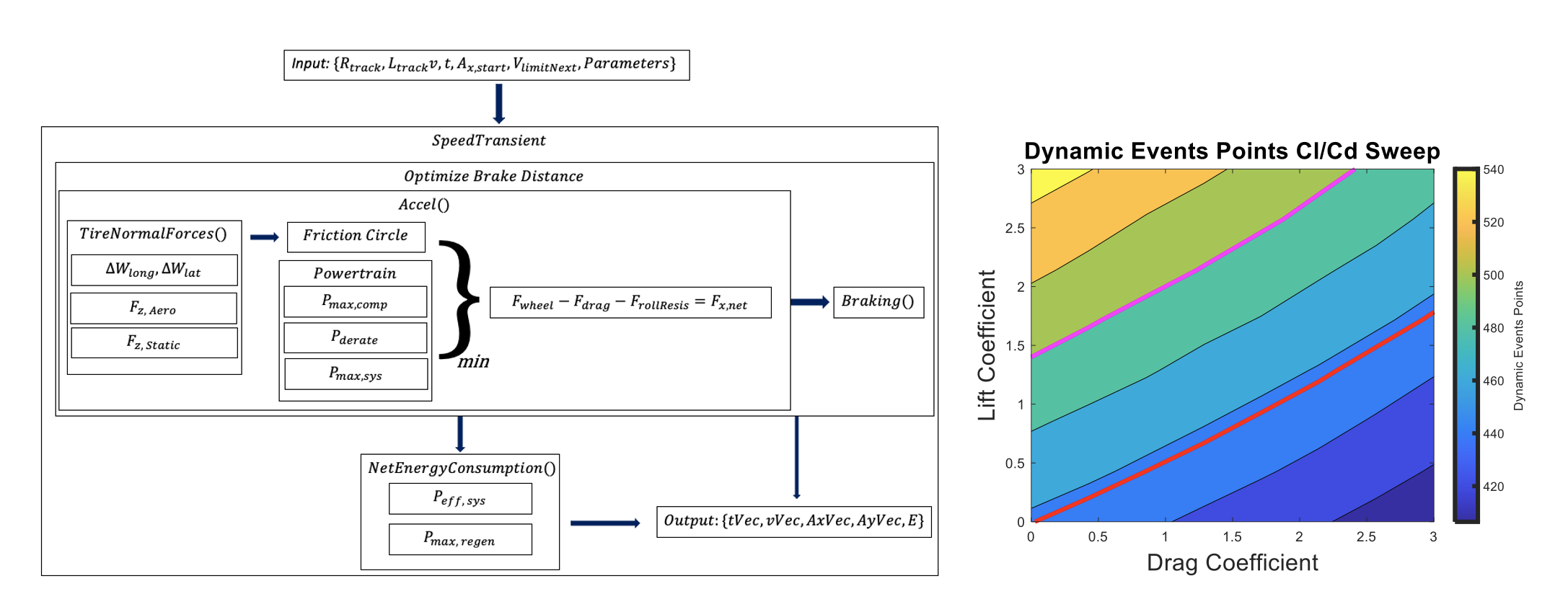

In race car engineering, everything has trade-offs and quantifying the effect of design decisions is the key to building a winning vehicle.

Imagine this: increasing the downforce by introducing bigger aerodynamic elements (i.e front/rear wings) suggests building a faster car because it increases max lateral acceleration.

In reality, however, adding additional aerodynamic elements has an unintended consequence of increasing energy consumption, leading to a heavier battery pack.

To understand these dynamic relationships, specific to our competition track, requires the use of numerical modeling.

By developing our own set of vehicle simulation tools, we were able to design a well balanced race car that maximizes point scoring.

A simplified diagram of our quesi-steady state lap sim.

The right figure shows a mass dependent sensitivity study of possible lift and drag coefficient values and its effects on anticipated points.

A simplified diagram of our quesi-steady state lap sim.

The right figure shows a mass dependent sensitivity study of possible lift and drag coefficient values and its effects on anticipated points.

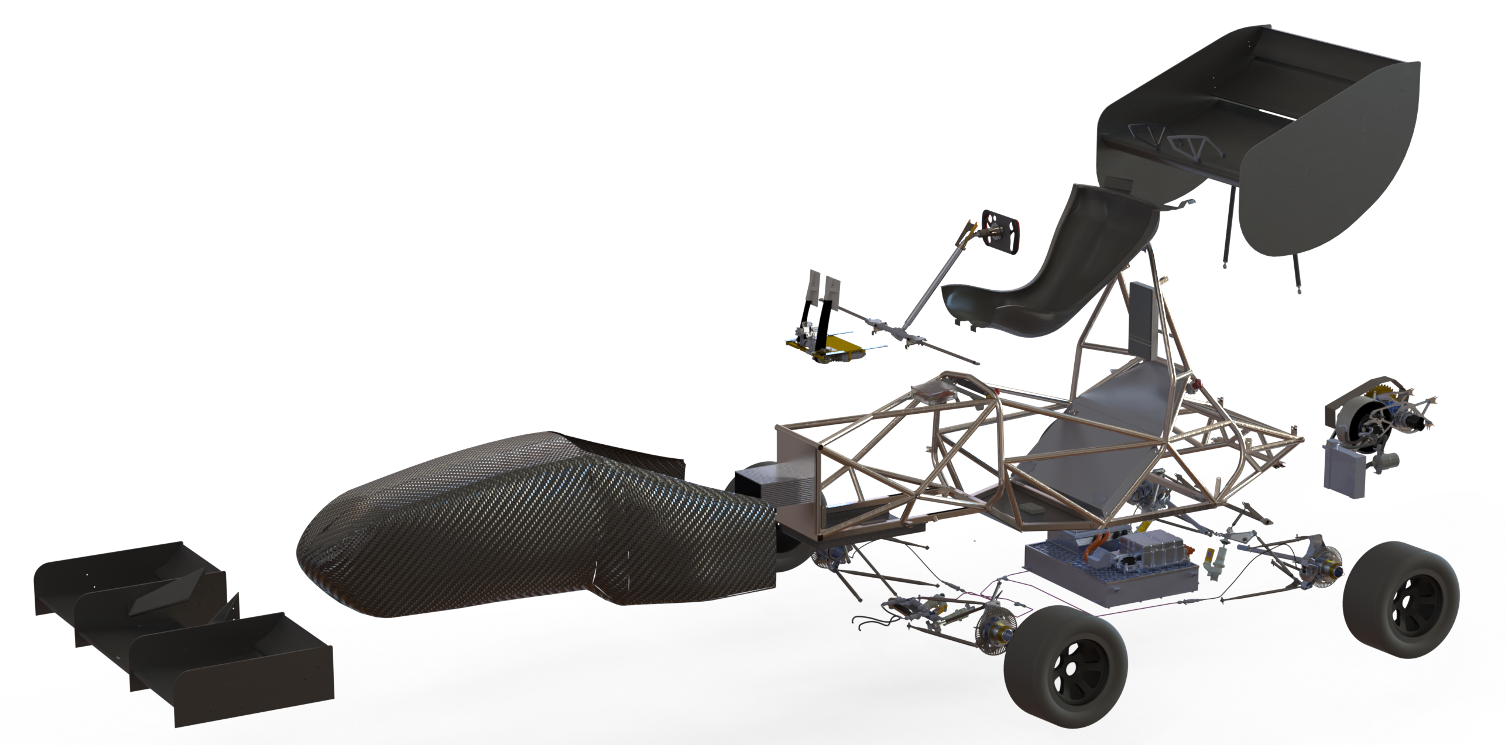

Once we have decided on the system level specifications, it is time to get our hands dirty with detailed component design.

This is an exceptional challenge, given the shear scale of engineering required to build a fully custom electric vehicle from scratch.

We approached this by dividing the work into respective sub-systems (i.e Propulsion, Suspension, High Voltage Controls, etc).

Then, we carefully integrate these sub-systems on a mechanical, electrical, and systems level back into the vehicle.

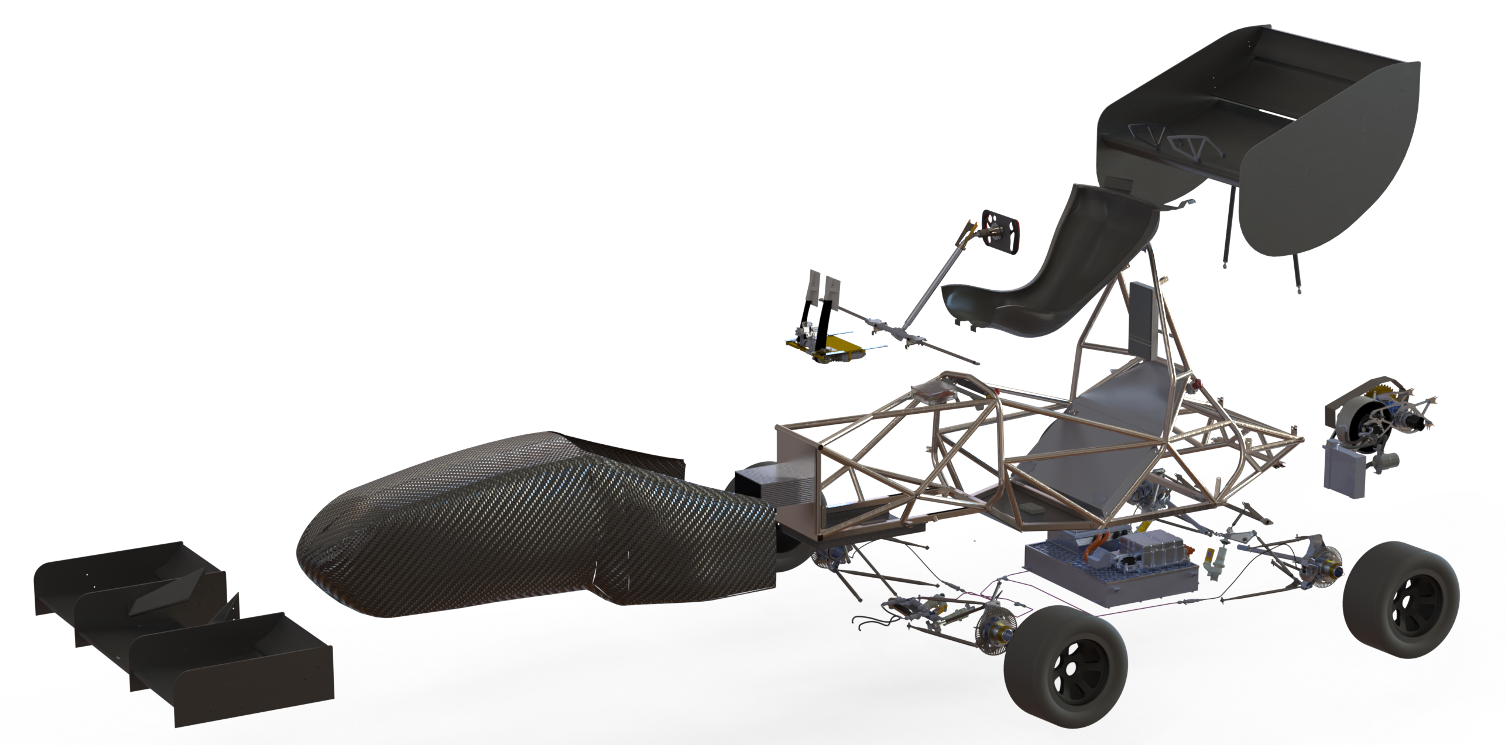

The exploded view below highlights the different mechanical subsystems that existed for HT06.

Exploded view rendering of HT06 highlighting the various sub-systems.

Exploded view rendering of HT06 highlighting the various sub-systems.

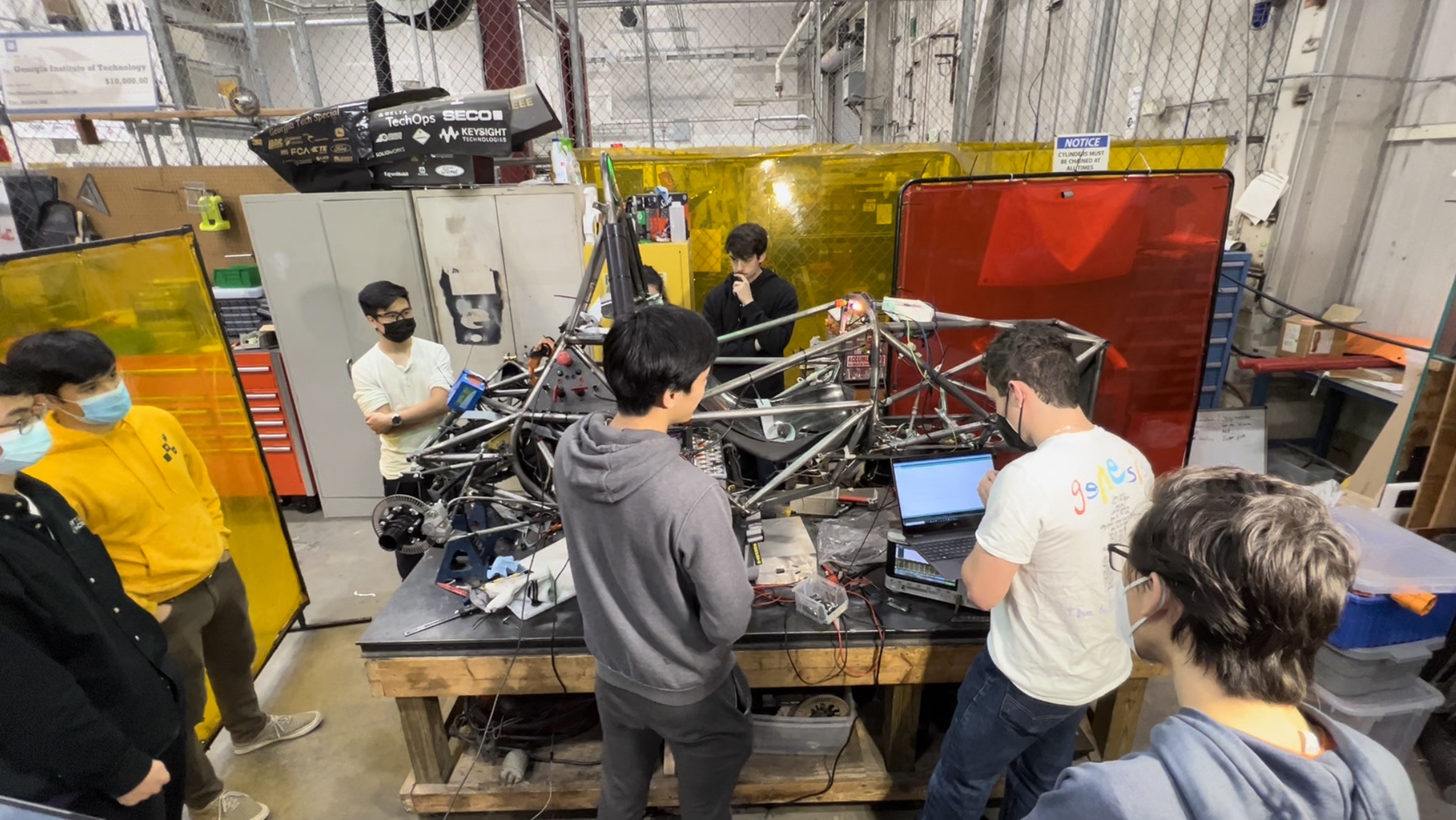

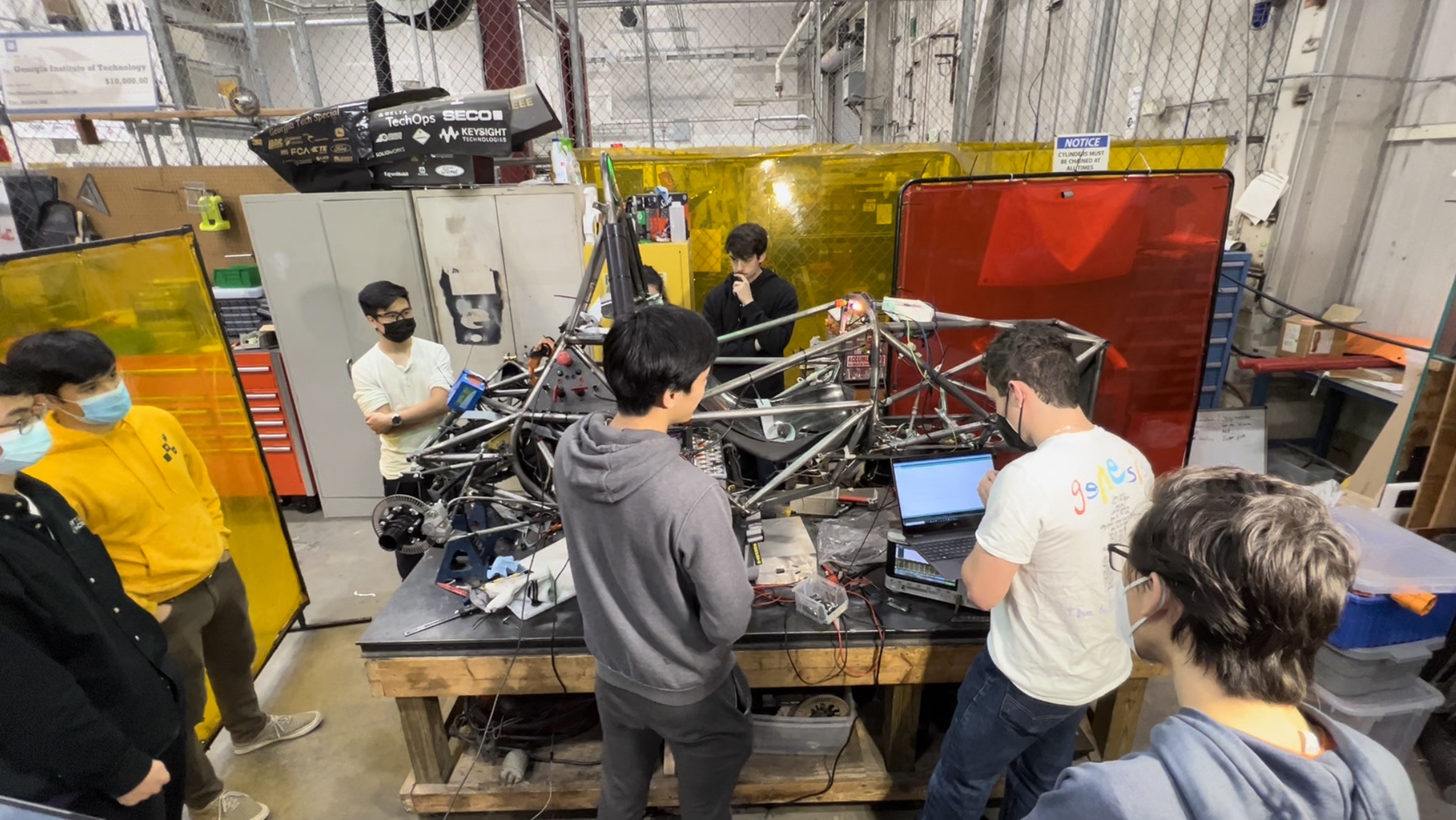

As a team, we often spent long nights at our shop space getting our hands dirty working on the car.

Often times, we were not able to account for all the design parameters ahead of fabricating the physical parts,

so the ability to prototype and test quickly was extremely important to us.

Photo capturing members debugging our traction controls system at our shop space.

Photo capturing members debugging our traction controls system at our shop space.

Hard data always beat simulation results. That is why we priortized testing, especially at a vehicle level.

As soon as we have a running 'skeleton' of HT06, we began testing.

We systematically verified and benchmarked each sub-system, holding data debriefs to determine our next course of action.

A functional HT06 skeleton headed to a test in the mechanical engineering building's parking lot.

A functional HT06 skeleton headed to a test in the mechanical engineering building's parking lot.

Competition & Results

We soared through most events at the competition, even earning a spot in the coveted design finals.

Approaching the final dynamic event of the competition, we were in contention for the championship against teams like University of Michigan.

However, disaster struck with 5 corners to go in the very last lap.

An unexpected voltage sag from one of our 84 battery cells triggered our safety system shutting off the car.

Ultimately, we managed to achieve a 3rd place overall amongst 58 teams.

Though it was a bittersweet result for the team, we are very proud of what we achieved.

Trophies from the 2022 Formula SAE Michigan Electric competition.

Trophies from the 2022 Formula SAE Michigan Electric competition.

You can also learn more about HyTech Racing on our Instagram.